Silica Sand / Quartz Sand

Silica sand, also well known as Quartz Sand. It was got from the broken and ground Silica Stone / Quartz Stone. Quartz stone is a non-metallic mineral, a hard, wearable, chemical properties, and stability of silicate minerals, the main mineral composition is SiO2. Quartz sand is an important industrial mineral raw materials, non-chemical dangerous goods, widely used in glass, casting, ceramics and fireproof materials, smelting ferrosilicon, metallurgical flux, metallurgy, construction, chemical, plastics, rubber, abrasive, filter and other industries.

High Purity Quartz Sand

High purity quartz sand is also named as silica sand, silica powder, and silica dioxide powder.

MiningValleys supplies high-purity quartz sands at >99.995% and 99.99% grades, which can be used for the semiconductor industry and normal quartz ingots respectively.

We adopt versatile production technology to ensure that yo’ll always be satisfied with our high quality silica. Our main comprehensive products are crystalline silica from silica powder, fused silica powder, coating grade silica powder, electrician grade silica powder, electron grade silica powder, general silica powder, transparent powder for artificial stone, crystal powder, high purity silica sand, high purity silica sand, and so on.

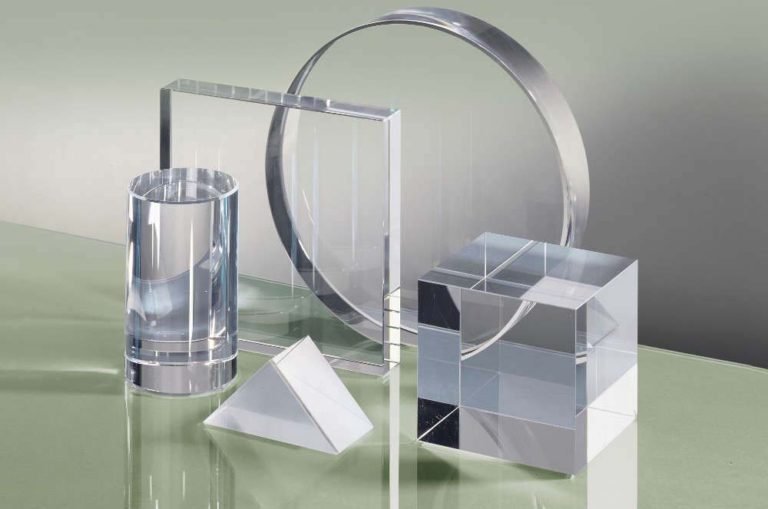

Quartz Sand Products

Silica Sand Manufacturing Process

Quartz Stone Crushing

- Firstly, quartz stone raw material will be sent into a jaw crusher for coarse crushing.

- And then, the crushed stones will be sent into sand making machine for further crushing and product shaping.

- The unqualified particle size will be re-sent into the crusher for further processing until they reach the standard.

Sand Washing

The finished particle size which meet the standard will be sent into sand washing machine for cleaning.

Scrubbing

Scrubbing is to remove the thin iron and muddy impurities on the surface of silica sand by mechanical force and the abrasive force between the sand grains and to further grind the unconsolidated mineral aggregates.

Purify Process

The composition of silica sand is complex, except for the iron-bearing minerals, there are often mica, feldspar, and clay minerals. Some impurities in silica sand, such as feldspar and mica, which cannot be removed by magnetic separation, but can be separated by different collectors. In general, the purity of silica sand can be increased to 99% after scrubbing, desliming, magnetic separation, and flotation.

Silica Sand Applications

High-purity silica sand for glass production

Quartz Ceramic such as tableware, floor ties, wall ties, etc.

Silica sand used for refractory silica bricks

High purity silica sand for foundry industry

Silica sand as water filter media for water filtration, water treatment

Water filter sand for swimming pool sand filter

Color silica sand for coating to improves the acid resistance of the coating

Silica sand used as filling material to improve the abrasion resistance of rubber or plastic.

Silica sand for artificial grass, prevent wrinkles or ripples, safe for kids and pets

Get a free quote

If you’re interested in ordering our silica quartz sand or flour, get in touch with MiningValleys today to request for quotation.